Agni Equipment Rack – 19” Enclosed Equipment Rack Series

The Agni Equipment Rack is a 19-inch enclosed rack cabinet designed for industrial, IT, telecom, and instrumentation applications. Available from 12U to 48U, it offers standardized mounting, high structural stability, and compliance with international standards.

Part Number: EQIP-RACK |

Product Overview

Agni Instruments Engineers India Private Limited is involved in the design and manufactures a wide range of 19-inch enclosed equipment rack systems, developed through in-house metal sheet fabrication as per the requirements of industrial, telecom, IT, and instrumentation applications.

The Agni Equipment Rack Series is a standardized structural enclosure that is designed to securely mount, organize, and protect equipment such as switches, routers, patch panels, and other Industrial Control and Automation, Public Address System, Fire Alarm, Safety, And CCTV Security Systems networking devices.

The rack system is designed in accordance with international and European EN standards, ensuring the reliablility of the structure and compatibility with equipment from multiple manufactures. In most modern installations in India, the 19-inch rack standard is used. This refers to the standardized mounting width of the equipment interface.

Enclosure Design & Construction

The Agni Equipment Rack Series is a standard enclosed cabinet solution that provides precision engineering, standardized mounting interfaces, compatible accessories, and foldable assembly construction.

The enclosure Layout facilitates:

- rack mount equipment mount in proper manner

- Long-term operational stability

Suitability for both domestic and international installations

Key Features & Benefits

- In-house manufactured for consistent quality and foldable assembling accuracy

- 19-inch standard mounting interface for multi-vendor compatibility

- wide range of U standard heights for flexible system design

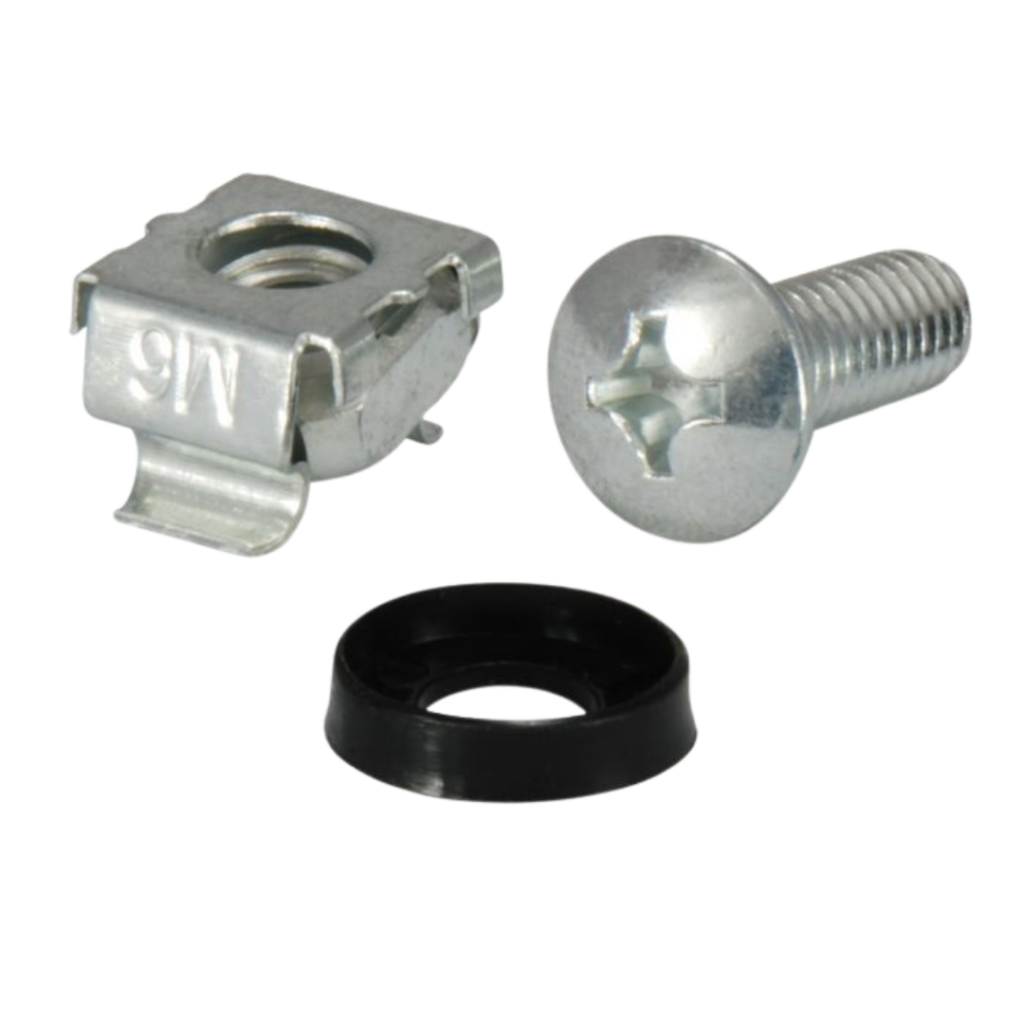

- Square-hole mounting compatible with cage nuts

- Suitable for floor or wall mount installations

- Optimized extra additional accessories

Available Rack Heights (U Sizes)

The Agni Equipment Rack Series is available in the following configurations:

|

Product Code |

Description |

|---|---|

|

AGNI EQIP-12UR |

12U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-16UR |

16U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-18UR |

18U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-20UR |

20U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-24UR |

24U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-26UR |

26U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-28UR |

28U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-30UR |

30U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-32UR |

32U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-36UR |

36U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-40UR |

40U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-42UR |

42U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-46UR |

46U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

|

AGNI EQIP-48UR |

48U 19” Free Standing Cabinet (W 600 mm × D 600 mm) |

Load Capacity

- Standard Configuration: Static load capacity up to 600 kg

- Enhanced (E) Configuration: Static load capacity up to 1000 kg

Technical Specification

Racks are usually made of sheet metal and come in different sizes, based on a standardized measurement called rack units (U or RU). Each unit is 1.75 inches (44.45 mm) high, and rack heights can typically range from a few units (for smaller, desktop-style racks) up to 12U or 48U for full-sized, floor-standing / wall mount racks. For example, a 24 U rack would provide 49.44 inches of vertical equipment space. The width of most equipment racks is standardized at 19 inches between the mounting posts, although a wider 24-inch variant exists, primarily used in telecom and data communications for mounting larger equipment. Equipment that’s designed to be mounted in these racks is often described as “rack-mount” or “rack-mountable” and is produced in various multiples of rack units. This can range from smaller 1U devices, like network switches or patch panels, up to much larger items, such as high-performance servers or storage systems, which may need to be housed in many rack units

Equipment Rack Accessories That Improve Performance

A rack without the right accessories is like a system without documentation. It works, but only until something changes. And something always changes.

The goal here is simple: reduce friction during operation, maintenance, and expansion.

Square holes compatible with cage nuts

Square-hole mounting with cage nuts is one of those decisions that quietly determines how easy or painful installation and maintenance will be over the life of the rack. When combined with cage nuts, square-hole mounting allows:- Secure load-bearing installation

- Repeatable mounting across different equipment types

Cooling Fan Trays and Ventilation Panels

- Support forced airflow exhaust from the rack enclosure

- Help in maintaining stable internal operating temperatures

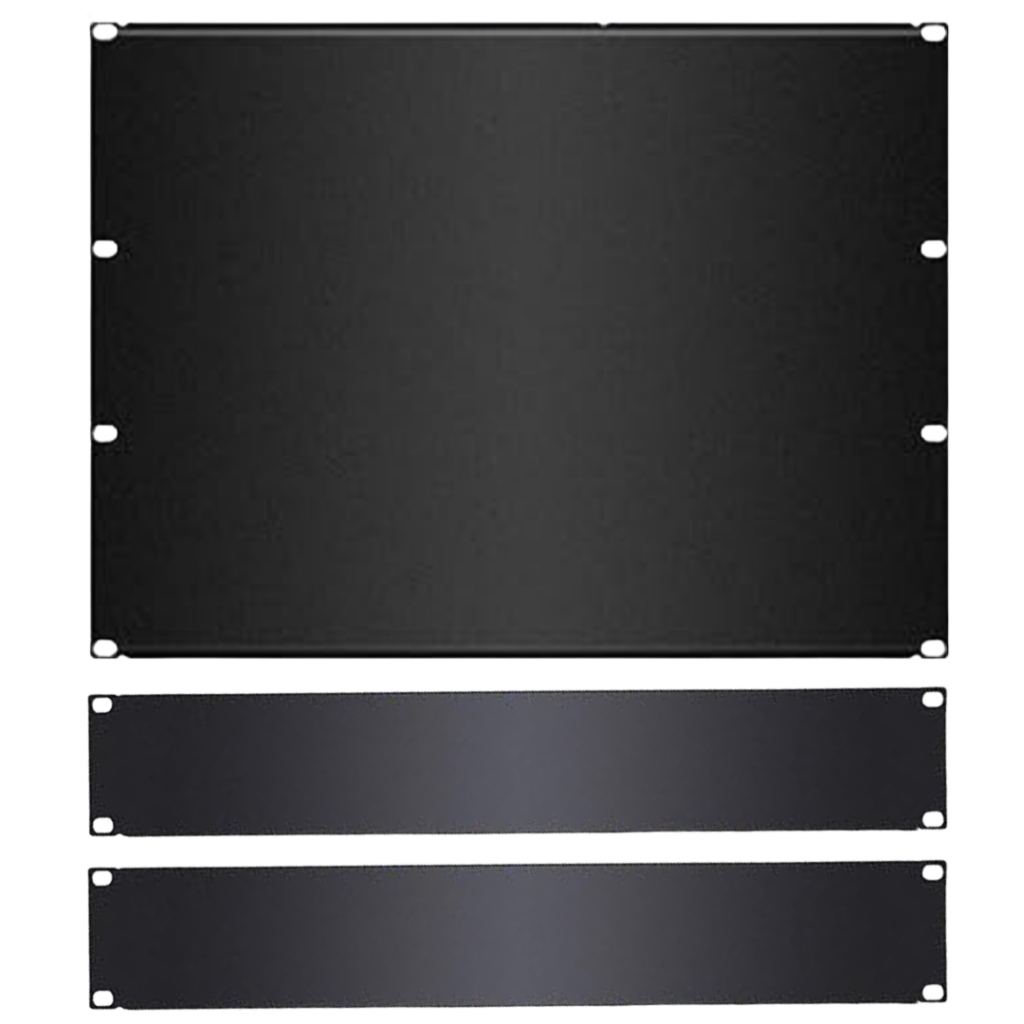

Blank Trays & Panels

Blank Trays

- Multi-purpose standard blank metal trays

- Support equipment should be able to be placed in flexible locations and organized internally

Blank Panels (1U, 2U, 3U, 4U)

- Improve vertical equipment placement visual order and layout clarity

- Improve management and vertical layout clarity

Power Distribution Units (PDUs)

Rack-mounted PDUs support organized mains power distribution by:- Providing centralized power pickup

- Reducing loose wiring and adapters

- Maintaining clear routing and safer electrical pluging

Cable Managers

- Support proper bundling, labeling, and separation of power and data cables

- Improve serviceability and reduce maintenance time

Side Arms

- Mounted along the sides of the equipment rack

- Support side-mounted accessories and structural stability

Cable Ties (4”, 6”, 8”, 9”)

- Used to secure and organize cables within the rack

- Maintain clear routing paths and reduce strain on connections

Common Applications

- IT And Networking Infrastructure

- Industrial Control And Automation

- Public Address System

- Fire Alarm, Safety, And CCTV Security Systems

- Data Rooms And Control Centers

- Infrastructure And Utility Installations

Equipment Rack Standards & Compliance

While the 19-inch rack standard originated from the American EIA specification, European and international norms ensure enhanced compatibility across global markets. Our racks conform to relevant standards including:

- EN / IEC 60529 – IP20 Ingress Protection

- ISO 9001 – Quality Management System

- EN 61587-1 – Mechanical Structures for Electronic Equipment

- IEC 297-1 – 19” Mounting Standard

- IEC 297-2 – Overall Cabinet Dimensions

- EN IEC 62368-1 – Audio/Video & ICT Equipment Safety

- CE Conformity as per EN 60950-1

- ISO 14001 – Environmental Management System

These standards define mechanical interfaces, mounting practices, and protection requirements, ensuring that equipment from multiple manufacturers can be safely mounted and seamlessly integrated within the rack system. European norms typically mandate metric cage nuts and screws fasteners (e.g., 6 mm) and standardized mounting interfaces.

Types of Equipment Racks Available

Floor-Standing Equipment Racks

Used where:

- Equipment density is high

- Load capacity requirements are significant

- Future expansion is planned

Common applications include data rooms, industrial plants, control rooms, and telecom equipment rooms.

Wall-Mount Equipment Racks

Used where:

- Floor space is limited

- Equipment count is low to moderate

Quick access is required

Indoor vs Outdoor Equipment Racks

- Indoor racks focus on organization, airflow, and access

- Outdoor racks are designed for exposure to dust, rain, and heat with higher ingress protection

Using an indoor rack outdoors leads to premature failure.

FAQ

What size equipment rack do I need?

Calculate current U requirements and add space for airflow and future expansion. A rack should not be fully populated at installation.

Are equipment racks suitable for different climate conditions?

Yes. When selected correctly, enclosed racks with proper ventilation manage dust, heat, humidity, and variable power conditions.

Can I install equipment from different brands in the same rack?

Yes. The 19-inch standard supports multi-vendor equipment mounting using standardized U spacing (1U = 44.45 mm).

Do equipment racks require certification in India?

Most commercial, industrial, and infrastructure projects expect compliance with recognized international safety and mechanical standards.